Knowing how to remove a stripped screw is an essential skill for homeowners, DIY enthusiasts, technicians, and professionals alike. A stripped screw occurs when the screw head becomes damaged, worn, or rounded, preventing the screwdriver from gripping properly. This frustrating problem can bring projects to a halt, damage materials, or even ruin expensive electronics if handled incorrectly.

This in-depth guide draws on hands-on experience, mechanical principles, and industry-approved methods to help you safely remove stripped screws from various materials, including wood, metal, plastic, laptops, and electronics. By following these proven techniques, you can minimize damage, save time, and avoid costly replacements.

Why Screws Get Stripped and Why Proper Removal Matters

Stripped screws usually result from using the wrong screwdriver size, applying excessive force, corrosion, or working with soft metals. Removing them incorrectly can worsen the damage, crack surrounding materials, or cause personal injury.

Understanding the material, space constraints, and screw condition is crucial before choosing a removal method. The sections below break down each scenario in detail with practical, step-by-step insights.

Also Read This:- How to Make Tea: The Ultimate Guide for Tea Lovers

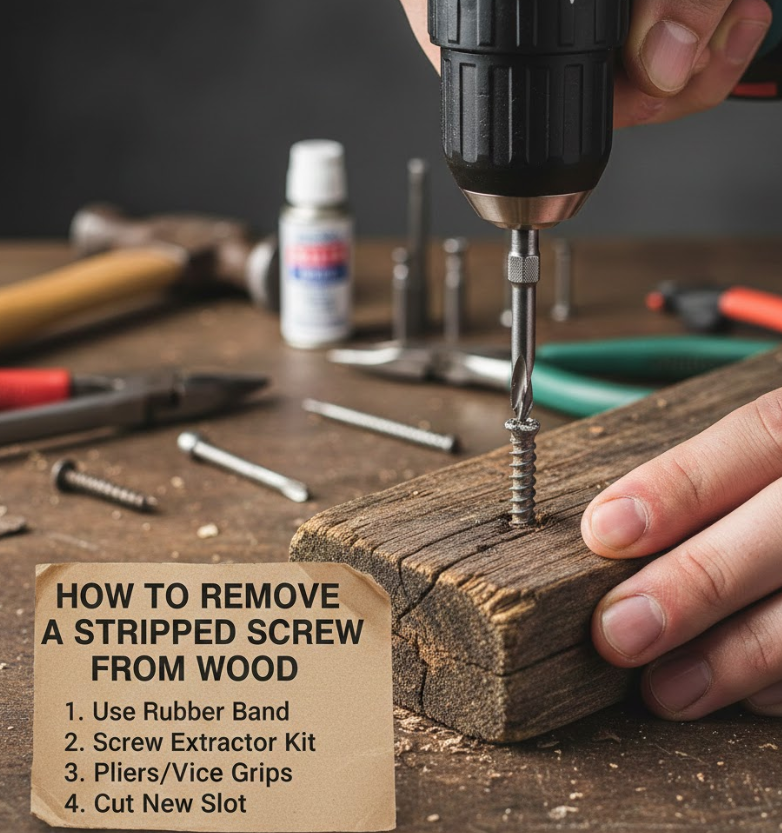

How to Remove a Stripped Screw from Wood

Removing a stripped screw from wood requires controlled force to avoid splintering or enlarging the hole.

• Wood is a forgiving material, but aggressive removal can weaken its grip, so applying gradual torque is critical.

• Start by pressing the screwdriver firmly into the stripped head while turning slowly to regain traction.

• If traction fails, lightly tap the screwdriver with a hammer to seat it deeper into the screw head fibers.

• Using locking pliers on a raised screw head provides added leverage without damaging the wood surface.

• Creating a new slot using a flathead screwdriver can restore turning ability.

• Applying a small amount of penetrating oil reduces friction between threads and wood fibers.

• Backing the screw out slowly prevents tearing the surrounding grain.

• For stubborn screws, an extractor can be used carefully without enlarging the hole.

• Heat application should be avoided as it may scorch or dry the wood.

• After removal, filling the hole with wood filler ensures structural integrity for reinstallation.

Also Read This:- How to Make Powdered Sugar at Home Easily

How to Remove a Stripped Screw from Metal

Metal surfaces demand precision to avoid stripping threads or scratching finishes.

• Metal screws often seize due to rust or galvanic corrosion, requiring lubrication before removal.

• Penetrating oil should be allowed to soak for several minutes to loosen thread bonds.

• Applying downward pressure with a hardened screwdriver improves grip on worn heads.

• Using a manual impact driver helps break corrosion without excessive torque.

• Locking pliers work well if the screw head protrudes slightly above the metal surface.

• Cutting a new slot with a rotary tool allows use of a flathead screwdriver.

• Screw extractors are especially effective in metal due to their reverse threading design.

• Drilling must be done slowly to avoid damaging internal threads.

• Heat can be applied cautiously to expand the metal and break corrosion.

• Cleaning threads after removal prevents future seizing issues.

Also Read This:- How to Season a Cast Iron Skillet: Expert Tips for Perfect Non-Stick Cooking

How to Remove a Stripped Screw from a Laptop or Electronics

Electronics require extreme care due to delicate internal components.

• Always power off and unplug the device before attempting removal.

• Use precision screwdrivers designed for electronics to avoid further stripping.

• Applying gentle downward pressure is more effective than forceful twisting.

• A small drop of isopropyl alcohol can help loosen micro screws without residue.

• Using a rubber band alternative like friction paste enhances grip safely.

• Screw extractors for electronics are smaller and reduce risk of board damage.

• Avoid drilling unless absolutely necessary, as metal shavings can short circuits.

• Magnetic mats help track tiny screws during removal.

• Working in a well-lit area improves accuracy and safety.

• If resistance persists, professional repair is often the safest option.

Also Read This:- How to Season a Cast Iron Skillet: Expert Tips for Perfect Non-Stick Cooking

How to Remove a Stripped Screw with a Screwdriver or Slot

This method focuses on restoring grip without additional tools.

• Switching to a slightly larger screwdriver may improve engagement.

• Pressing downward firmly increases friction between the driver and screw head.

• Tapping the screwdriver lightly helps it seat deeper into the damaged slot.

• Cutting a straight slot creates a fresh driving surface.

• Flathead drivers often provide more torque than Phillips in stripped situations.

• Manual turning is safer than powered tools to avoid cam-out.

• Maintaining alignment prevents further rounding of the head.

• Slow, controlled movement reduces slippage.

• This method works best when the screw is not seized.

• Stop immediately if additional stripping occurs.

Also Read This:- What Does a Game Publisher Do? A Complete and In-Depth Explanation

How to Remove a Stripped Screw from Plastic

Plastic surfaces are prone to cracking and melting.

• Use minimal force to avoid stripping plastic threads.

• Grip-enhancing materials improve traction without pressure.

• Avoid heat as plastic can deform quickly.

• Precision tools reduce risk of surface damage.

• Backing the screw out incrementally reduces stress.

• Locking pliers are effective if the head is exposed.

• Cutting a slot is safer than drilling.

• Plastic-safe extractors minimize cracking.

• Slow removal protects the surrounding housing.

• Reinforce the hole after removal if necessary.

Also Read This:- What Does Media Upload Mean on Snapchat? A Complete User-Friendly Guide

How to Remove a Stripped Screw Head with an Extractor or Drill

Extractors are among the most reliable solutions.

• Screw extractors bite into the damaged head using reverse threads.

• Drilling a pilot hole ensures proper extractor seating.

• Low speed prevents overheating and breakage.

• Applying steady torque avoids snapping the extractor.

• Hardened extractors work best on metal screws.

• Drills should be used only when other methods fail.

• Left-hand drill bits sometimes remove screws without extractors.

• Always wear eye protection during drilling.

• Clean debris before reinserting new screws.

• Replace damaged screws to prevent recurrence.

Also Read This:- What Does Media Upload Mean on Snapchat? A Complete User-Friendly Guide

How to Remove a Stripped Screw with Household Alternatives

Some situations call for creative solutions.

• Duct tape increases friction between the screwdriver and screw head.

• Rubber bands offer similar grip enhancement for lightly stripped screws.

• Friction compounds outperform tape for heavy-duty applications.

• These methods are low-risk and non-destructive.

• Best suited for small or partially stripped screws.

• Press firmly to prevent slippage.

• Avoid excessive torque to maintain grip.

• Replace improvised materials frequently.

• Combine with downward pressure for best results.

• If unsuccessful, switch to mechanical tools.

Also Read This:- What Does Eco Car Mean: A Complete and Practical Explanation

How to Remove a Stripped Screw in Tight Spaces or Fixtures

Confined areas require patience and specialized tools.

• Right-angle screwdrivers improve access.

• Stubby drivers reduce leverage but increase control.

• Magnetic tips prevent dropped screws.

• Working slowly avoids tool slippage.

• Compact extractors are ideal for fixtures.

• Avoid power tools in restricted areas.

• Remove surrounding components if possible.

• Adequate lighting improves precision.

• Protect surfaces with masking tape.

• Plan removal strategy before starting.

Also Read This:- How to Make Microsoft Edge the Default Browser: A Complete Guide

How to Remove a Stripped Screw from a Door Knob or Shower Faucet

Fixtures often involve hidden fasteners.

• Identify set screws before applying force.

• Penetrating oil helps with moisture-exposed screws.

• Flathead slots are often effective.

• Avoid scratching visible finishes.

• Manual tools offer better control.

• Use cloth or tape to protect surfaces.

• Extractors work well for recessed screws.

• Replace screws with corrosion-resistant alternatives.

• Ensure alignment during reassembly.

• Regular maintenance prevents future stripping.

Conclusion: Mastering How to Remove a Stripped Screw

Learning how to remove a stripped screw empowers you to tackle repairs confidently without damaging materials or tools. By understanding the material, selecting the right method, and applying controlled techniques, nearly any stripped screw can be removed safely. Whether working with wood, metal, electronics, or fixtures, patience and precision are the keys to success.

Frequently Asked Questions

Can I remove a stripped screw without special tools?

Yes, friction-based methods or slot creation often work for lightly stripped screws.

Is drilling always safe?

Drilling should be a last resort, especially near electronics or delicate materials.

How do I prevent screws from stripping again?

Use the correct driver size, apply steady pressure, and avoid overtightening.

Visit For More Information go to:- Virtualsmagazine